- English

- Afrikaans

- שפה עברית

- Cymraeg

- беларускі

- Hrvatski

- Кыргыз тили

- Kurdî

- IsiXhosa

- Zulu

- Punjabi

- Somali

- O'zbek

- Հայերեն

- Sundanese

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- नेपाली

- Burmese

- ລາວ

- Қазақша

- Македонски

- Română

- Srpski језик

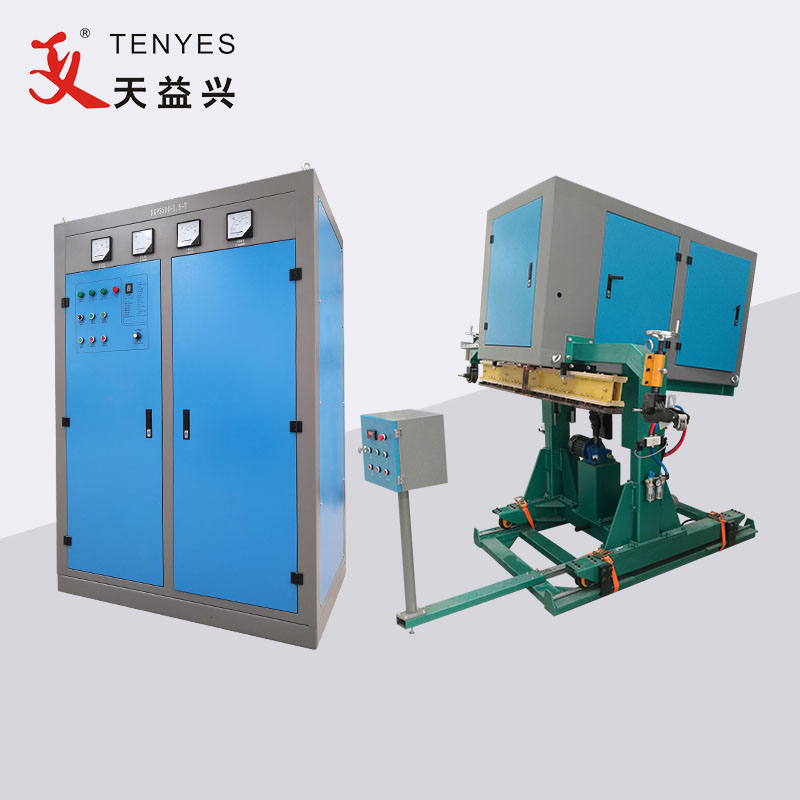

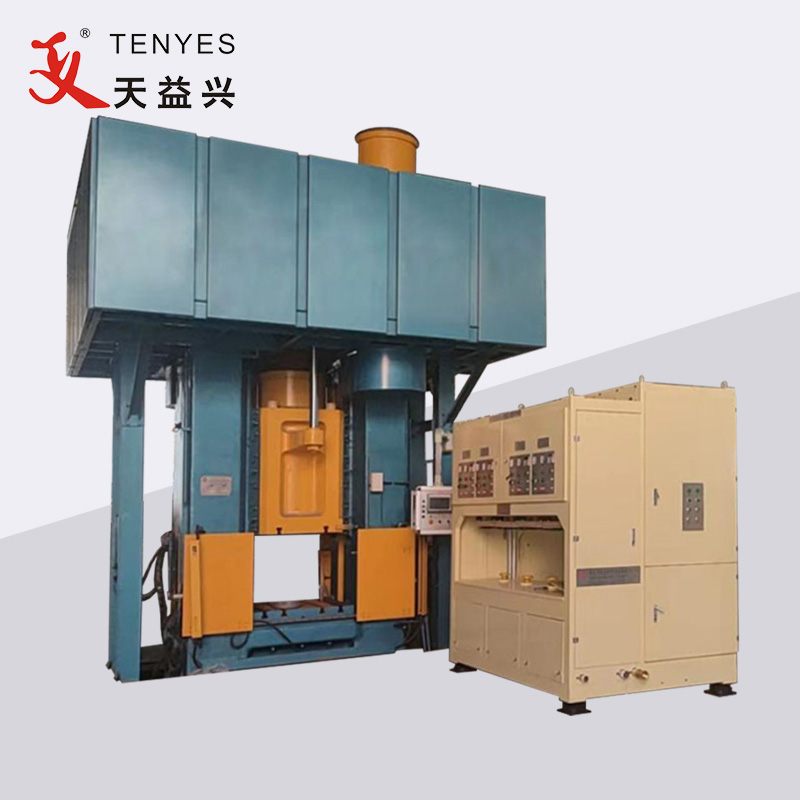

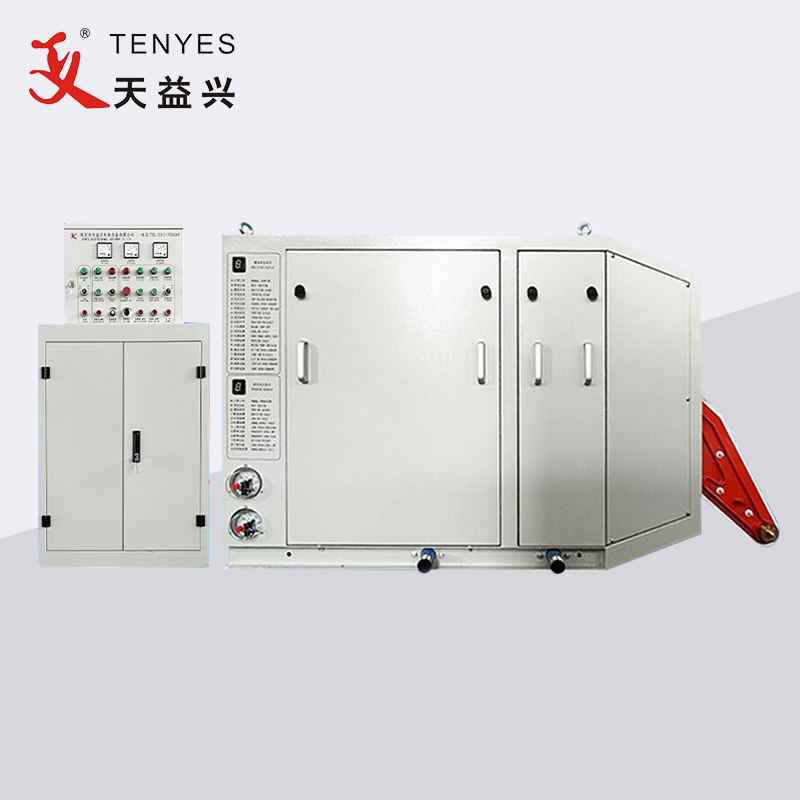

I-SiC-MOSFET Solid State High Frequency Pipe Welder

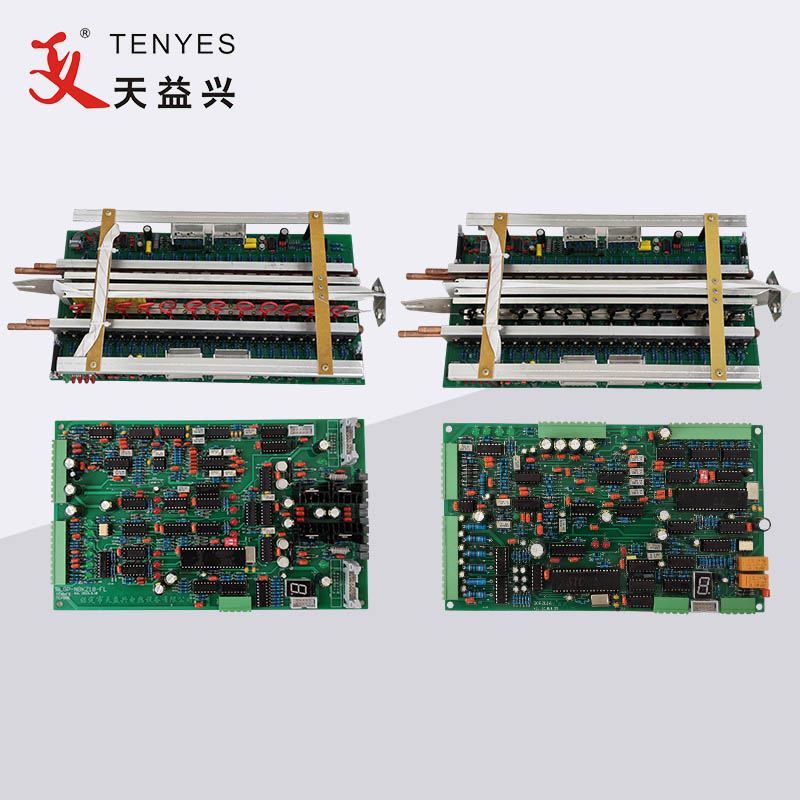

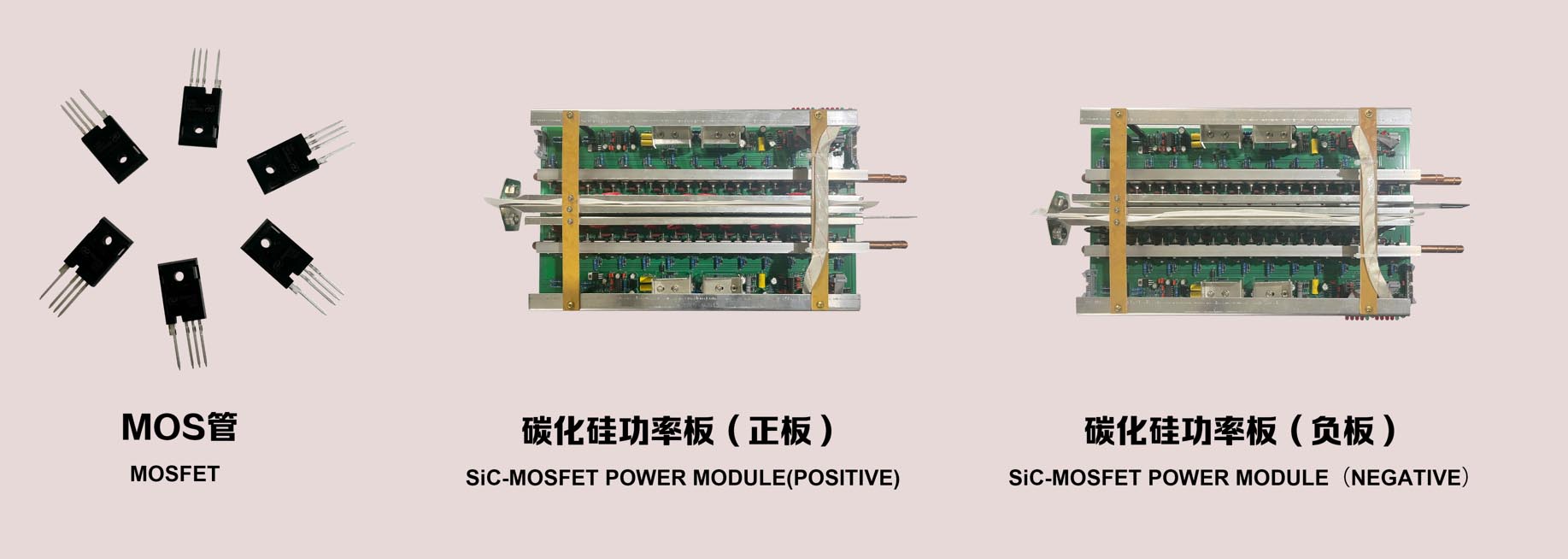

I-SiC-MOSFET Solid State High Frequency Pipe Welder isebenzisa izinto ze-semiconductor yesizukulwane sesithathu esikhundleni se-low-voltage evamile ye-mosfet tube.I-mosfet ye-SiC inokushisa Okuphezulu nokumelana nokucindezela okukhulu.I-SiC mosfet esetshenziswa ikakhulukazi kumabhodi amamojula amandla.Lolu hlobo lwamabhodi amandla asetshenziswayo esimweni esiqinile ipayipi lokushisela imvamisa ephezulu.

Thumela Uphenyo

Njengoba ubuchwepheshe buthuthuka, muva nje i-solid state high frequency welder isebenzisa impahla ye-semiconductor yesizukulwane sesithathu ebizwa ngokuthi i-SiC-MOSFET.

I-Third Generation Semiconductor Materials Izici Zokusebenza Ze-SiC-MOSFET

1. Ukushisa okuphezulu nokumelana nokucindezela okukhulu: I-SiC inegebe elibanzi lebhande cishe izikhathi ezi-3 kune-Si, ngakho ingakwazi ukubona amadivaysi amandla angasebenza ngokuzinzile ngisho nangaphansi kwezimo zokushisa eziphezulu. Amandla enkambu yokuhlukaniswa kwe-insulation ye-SiC aphindwe izikhathi ezingu-10 ku-Si, ngakho-ke kungenzeka ukwenza amadivayisi anamandla kagesi aphezulu anokugxiliswa kwe-doping okuphezulu kanye nongqimba oluncane lwefilimu lokukhukhumala oluwugqinsi oluqhathaniswa nemishini ye-Si.

2. Device miniaturization and lightweight: Silicon carbide devices have higher thermal conductivity and power density, which can simplify the heat dissipation system, so as to achieve device miniaturization and lightweight.

3. Low loss and high frequency: The working frequency of silicon carbide devices can reach 10 times that of silicon-based devices, and the efficiency does not decrease with the increase of working frequency, which can reduce the energy loss by nearly 50%; At the same time, due to the increase of frequency, the volume of peripheral components such as inductance and transformers is reduced, and the volume and other components cost after the composition of the system are reduced.

Izinzuzo ze-SiC-MOSFET Solid State High Frequency Pipe Welder

Ukulahlekelwa okuphansi ngo-1.60% kunamadivayisi e-Si-MOSFET, ukusebenza kahle kwe-welder inverter kwenyusa ngaphezu kuka-10%, ukusebenza kahle kwe-welding kwenyusa ngaphezu kuka-5%.

2.I-Single SiC-MOSFET ukuminyana kwamandla kukhulu, ubuningi obuhlanganisiwe buncishiswa ngokufanele, okunciphisa ngokuqondile amaphuzu amaphutha nemisebe yangaphandle kazibuthe, futhi kuthuthukisa ukuthembeka kweyunithi yamandla e-inverter.

I-3.SiC-MOSFET imelana ne-voltage ephakeme kune-Si-MOSFET yasekuqaleni, i-voltage elinganiselwe ye-welder DC inyusiwe ngokufanele ngaphansi kwesisekelo sokuqinisekisa ukuphepha(280VDC ye-parallel resonant welder kanye ne-500VDC yochungechunge lwe-resonant welder).Isici samandla sohlangothi lwegridi ≥ 0.94 .

4.Ukulahleka kwedivayisi entsha ye-SiC-MOSFET kungama-40% kuphela e-Si-MOSFET, ngaphansi kwezimo ezithile zokupholisa, ukushintsha imvamisa kungaba ngaphezulu, uchungechunge lwe-Si-MOSFET welder lusebenzisa ubuchwepheshe bokuphindaphindeka kabili, yamukela i-SiC-MOSFET engakwazi ukuklama nokukhiqiza ngokuqondile 600KHz imvamisa yokushisela imvamisa ephezulu.

5.Ukwenyuka kwamandla kagesi we-SiC-MOSFET welder DC, isici samandla egridi siphezulu, i-AC yamanje incane, i-harmonic yamanje incane, izindleko zekhasimende zokuphakela nokusabalalisa kukagesi ziyancipha kakhulu, kanye nokusebenza kahle kokuphakelwa kukagesi kuthuthukiswa ngempumelelo.